Why do online testers need calibration?

The main reason for calibrating online testers is to ensure the accuracy and reliability of their measurement results. Calibration is a process through which measuring instruments can be compared with known standards, allowing for adjustments and calibrations to improve measurement precision. Here are several important reasons why online testers need calibration:

Accuracy assurance: The calibration process helps verify the accuracy of measuring instruments. By comparing with known standards, any potential deviations or errors can be detected and corrected to ensure the accuracy of measurement results.

Traceability: Calibration establishes a relationship between measuring instruments and international or national standards, providing traceability. This means that measurement results can be traced back to known standards, ensuring consistency and comparability of measurement data.

Quality control: Calibration is part of quality control, helping to ensure that online testers maintain consistent performance levels throughout their lifespan. This is crucial for continuously monitoring and controlling various process variables, especially in industrial and laboratory environments.

Environmental impact correction: Measuring instruments may be affected by environmental conditions such as temperature and humidity. Regular calibration can identify and correct these environmental impacts to ensure measurement results are not disturbed by external conditions.

Regulatory and standard requirements: Many industries and application areas have strict regulatory and standard requirements for the accuracy of measuring equipment. Regular calibration is a method to comply with these regulations and standards.

Overall, calibrating online testers can enhance the credibility of measurements, ensuring data accuracy in production and experimental processes, thus providing a reliable basis for correct decision-making.

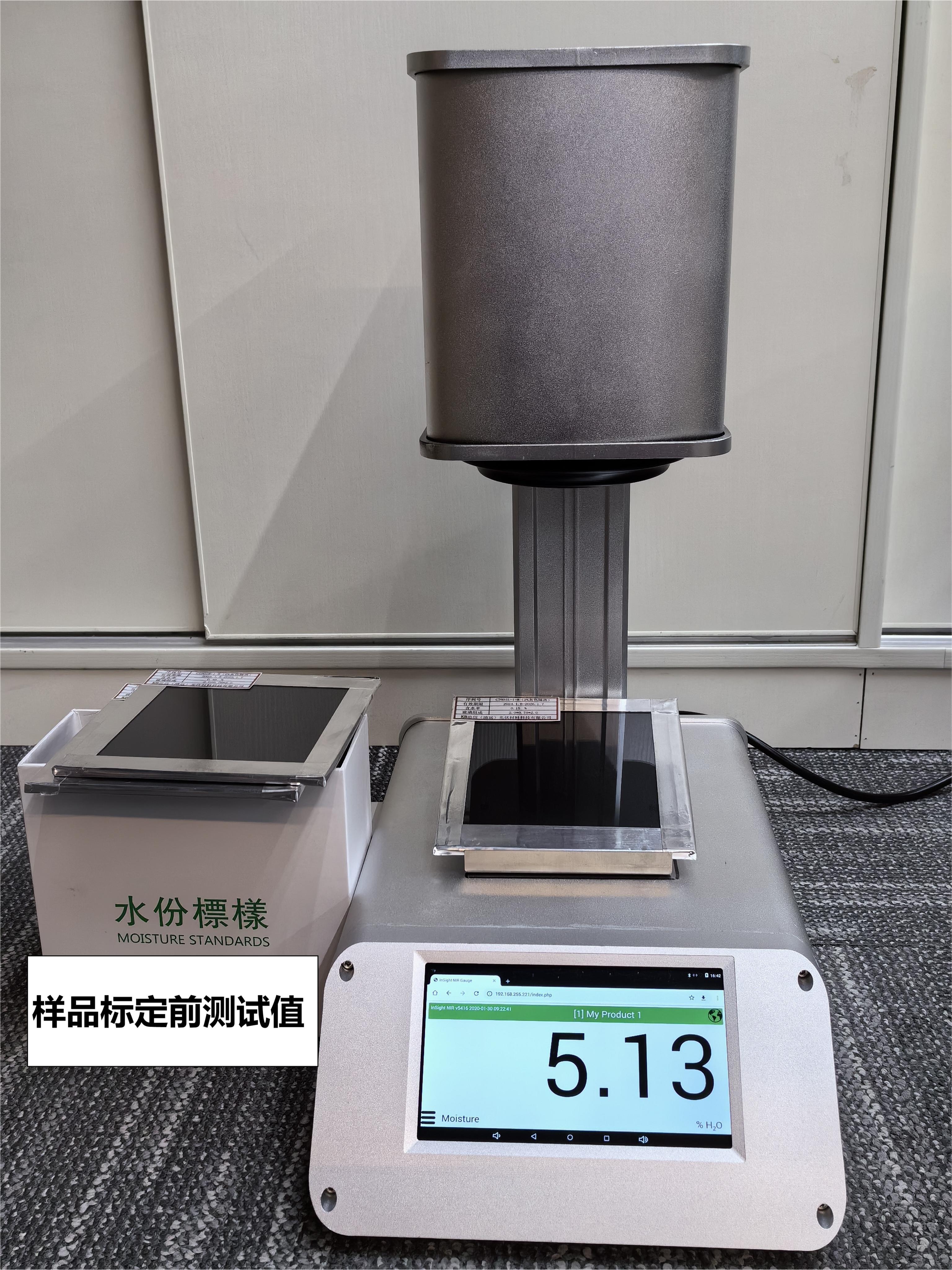

Tongfei Technology Desktop Moisture Tester

Reference Reading

1. Known standards: This means that during instrument calibration, widely recognized and proven accurate reference standards or measuring tools are used. These standards are usually established by national or international standardization organizations and are widely accepted and adopted. Here are some common examples of known standards:

National standards: Various standards have been established by the country in different fields, including measurement and testing standards. These standards are usually issued by national standard organizations or relevant departments and are used as calibration benchmarks for various measuring instruments.

International standards: International standards are established by the International Organization for Standardization (ISO) and cover multiple countries and regions. In some industries, it is common practice to use ISO standards for calibration.

Laboratory certification: Some specialized laboratories are authorized as reference laboratories and provide accurate measurement standards. By sending instruments to these laboratories, high-precision calibration can be performed.

Manufacturer standards: Some instrument manufacturers provide their own standards for calibrating the equipment they produce. This often involves using samples with known values to adjust the instrument's settings.

Physical constants: Some standards involve fundamental physical constants, such as the speed of light and gravitational acceleration. These constants are known and can serve as benchmarks for calibrating instruments.

During the calibration process, the output of the measuring instrument is compared with these known standards, and adjustments are made based on the differences. This helps ensure that the measuring instrument can provide accurate and reliable results during use.

2. Factors affecting accuracy

Accuracy of standards: The accuracy of the calibrated instrument directly depends on the accuracy of the reference standards used. If the reference standards themselves are not accurate enough, the calibration process cannot provide high-precision corrections. Therefore, it is crucial to select and maintain accurate reference standards.

Accuracy of the calibration procedure: The design and execution of the calibration process are critical for ensuring instrument accuracy. The calibration procedure should consider all possible sources of error and take appropriate steps to minimize or correct these errors.

Environmental conditions: Environmental conditions during calibration, such as temperature and humidity, may affect measurement results. Therefore, these environmental factors need to be controlled during the calibration process or environmental corrections made to ensure accuracy.

Stability of the instrument: The stability and precision of the instrument itself are also key factors in calibration. If the instrument experiences significant drift or changes in a short period, the effectiveness of the calibration may be affected. Therefore, the stability of the instrument needs to be effectively monitored and maintained.

Human error: The skills and experience of the operator can also affect the accuracy of calibration. Calibration should be performed by trained professionals who understand the calibration procedures and can execute them correctly.

Measurement uncertainty: Calibration results are often accompanied by measurement uncertainty. This is a parameter used to describe the range of uncertainty in measurement results. Calibration reports typically provide information on measurement uncertainty to help users understand the credibility of the measurement results.

Frequency of calibration: The frequency of calibration also affects accuracy. Regular calibration helps detect and correct instrument drift or changes in a timely manner, ensuring that the instrument remains accurate throughout its lifespan.

Address: Room 604, No.33 Jianshe Sixth Road, Yuexiu District, Guangzhou

Telephone:+86-(020)8618 7789

E-mail:mail@tongfei.net | sales@tongfei.net

Certificate Report Query,Document Information Query,Recruitment Management,Anti-counterfeiting query,3D Presentation

Copyright©2024 Guangzhou Tongfei Technology Co., Ltd. All Rights Reserved